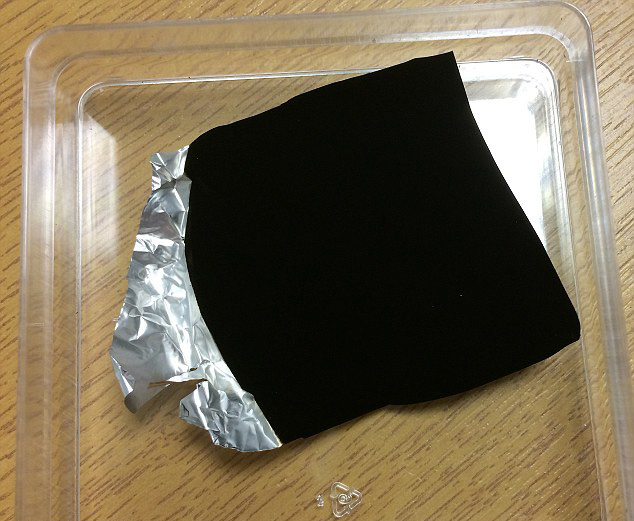

A company in the UK is using nanotechnology to capture light, and achieve new levels of range and sensitivity in a breakthrough “super black” material. Check this out:

Vantablack – created by Surrey NanoSystems – is revolutionary in its ability to be applied to lightweight, temperature-sensitive structures such as aluminium whilst absorbing 99.96% of incident radiation, the highest level ever recorded.

“Vantablack is a major breakthrough by UK industry in the application of nanotechnology to optical instrumentation”, says Ben Jensen, the company’s Chief Technology Officer. “It reduces stray-light, improving the ability of sensitive telescopes to see the faintest stars, and allows the use of smaller, lighter sources in space-borne black body calibration systems. Its ultra-low reflectance improves the sensitivity of terrestrial, space and air-borne instrumentation.”

Vantablack is the result of applying a low-temperature carbon nanotube growth process. The manufacture of “super-black” carbon nanotube materials has traditionally required high temperatures – preventing their direct application to sensitive electronics or materials with relatively low melting points. This, along with poor adhesion, prevented their application to critical space and air-borne instrumentation. Over a period of two years, the development and testing programme by Surrey NanoSystems successfully transferred its low-temperature manufacturing process from silicon to aluminium structures and pyroelectric sensors. Qualification to European Cooperation on Space Standardisation (ECSS) standards was also achieved.

Vantablack has the highest thermal conductivity and lowest mass-volume of any material that can be used in high-emissivity applications. It has virtually undetectable levels of outgassing and particle fallout – thus eliminating a key source of contamination in sensitive imaging systems. It can withstand launch shock, staging and long-term vibration, and is suitable for coating internal components, such as apertures, baffles, cold shields and Micro Electro Mechanical Systems (MEMS)-type optical sensors.

“We are now scaling up production to meet the requirements of our first customers in the defence and space sectors, and have already delivered our first orders. Our strategy includes both the provision of a sub-contract coating service from our own UK facility, and the formation of technology transfer agreements with various international partners”, added Jensen.

As a spin-off from its work in applying nanomaterials to semiconductor device fabrication, Surrey NanoSystems’ manufacturing process also enables Vantablack to be applied to flat and three-dimensional structures in precise patterns with sub-micron resolution.